Engineering projects require a variety of skills no matter what the project involves or its size. From grading, stormwater design, utilities, and project layout, our staff has the experience and knwoledge to get the job done.

Brigham Hill Residential Subdivision

Phase IV, Attleboro, MA

Commercial Site Plan

Providence Bagel, Attleboro, MA

Elderly Housing

Brookhaven at Lexington, MA

Geotechnical Engineering

National Grid

Laboratory and R&D Facility

23 Elm Street, Watertown, MA

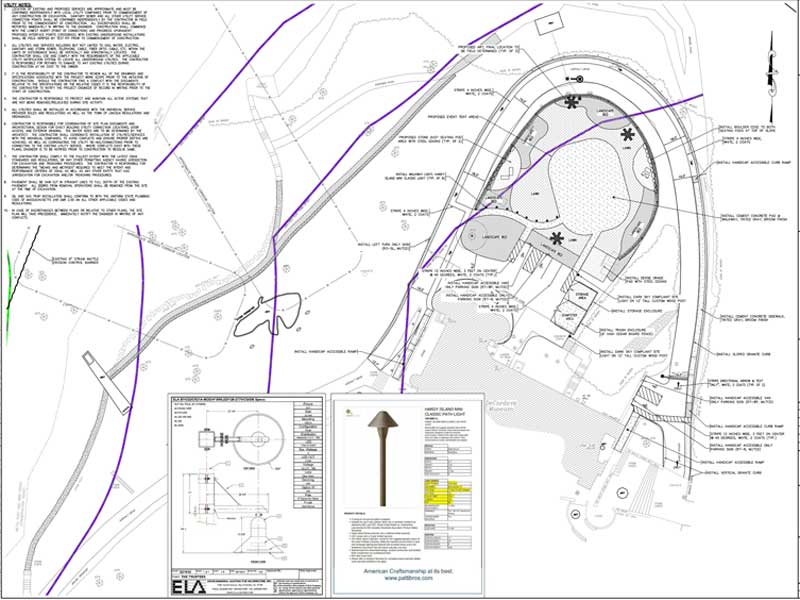

Public Access and Event Facility

DeCordova Sculpture Park and Museum, Lincoln, MA

The Highlands Residential Cluster Development

Attleboro, MA